Environmentally friendly packaging solution implemented at Cobra Sport

Posted by CobraSportExhausts Admin

Here at Cobra Sport, we are more than aware that the prime focus of our business is often not regarded in the best light by those with a more eco-conscious mindset. We can assure you though, that where possible, we are making efforts as a company to do our bit for the environment.

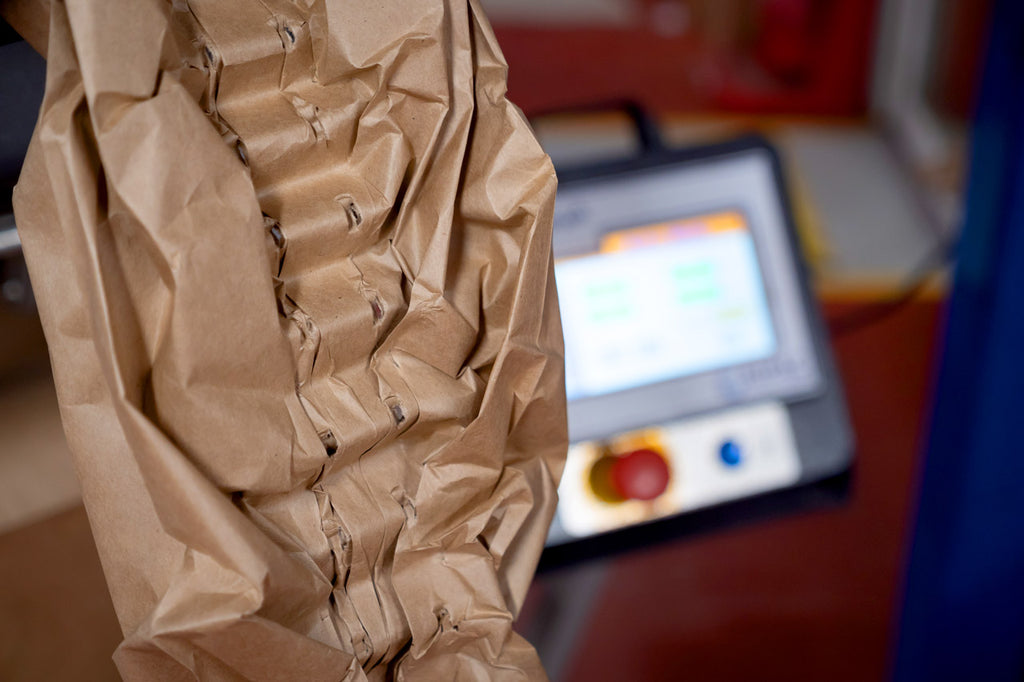

A prime example of this is the latest investment in our packing department: a Nuevpac X-Pad+™ paper packaging machine.

This state-of-the-art device allows us to cut down our company’s carbon footprint by reducing the amount of packaging, and therefore waste, that is needed when packing our performance exhaust components. And the best thing about it? The highly-protective cushioning material that the Nuevopac uses is made from 100% recycled paper, meaning that our whole packaging process is now almost completely eco-friendly and sustainable.

Whilst our packaging process does still require the use of bubble wrap to add an extra barrier of protection to our exhausts, we are committed, as a company, to seeking out a more environmentally-friendly substitute to this material in order to make the process 100% sustainable.

On the subject of Cobra Sport’s eco-credentials, it is also worth noting that all of our performance exhausts are made from T304-grade Stainless Steel which, like the packaging that they arrive in, is completely recyclable. The BSSA (British Stainless Steel Association) states: ‘Stainless Steel is 100% recycleable and its long term life makes it an ideal environmental performer, much better than many other materials. Stainless Steel products are designed to have a long life; often spanning over several decades. This long term life generally is the reason for choosing stainless steel in the first place.’

So when you’re looking to enhance the sound, looks and quality of your vehicle by purchasing a Cobra Sport Exhaust, be assured that it was manufactured and packaged in the most eco-friendly way possible.